Network Cabling

MPO/MTP Fiber Patch Cable Types and Applications

As data center bandwidth and network connectivity continue to increase, traditional duplex fiber patch cords such as LC patch cords are no longer sufficient. To solve this problem, and MPO/MTP fiber that houses more fibers in a multi-fiber MPO/MTP connector was introduced as a practical solution for high-density cabling in data centers. Understanding the differences between the various types of MPO/MTP in a high-density cabling system can make a big difference in the speed and configuration of your network. In this guide, we’ll help you understand the basic types and differences between the various MPO/MTP fiber cables so you can determine which type of MPO/MTP fiber cable is best for your network needs.

MPO/MTP Fiber Cable Overview

MPO (Multi-Fiber Push-On) is the first generation of clip-on clamp-on multicore fiber optic connectors. MTP is a registered trademark of US Conec Ltd. and is an advanced version of MPO with the better mechanical and optical performance. They look similar and are fully compatible and interchangeable. MPO/MTP fiber optic cable consists of MPO/MTP connector and optical fiber. MPO/MTP fiber optic connector contains optical fiber, sheath, coupling assembly, metal ring, pins, dust cap, etc. And the pin section is divided into two forms: male and female. In addition, one side of the connector body has a “key”, there are “concave and convex”, used to limit the relative position of the connector, that is, P1, P2, etc. Usually, there is a connector body side called “white dot “MPO/MTP connectors greatly increase fiber optic cable density and save circuit card and rack space, making them ideal for current data center cabling and future network speed upgrades.

What are the different types of MPO/MTP fiber cable, and how can you choose the right ones as your business grows and your networking needs expand?

Classification by MPO/MTP Function

The mains types include MPO/MTP patch cable, MPO/MTP trunk cable, and MPO/MTP breakout cable, they are ideal for high-density cabling networks and provide better network capacity and flexibility.

What is MPO/MTP Patch Cable

MPO/MTP patch cables are widely used in data centers to connect high-speed MPO/MTP optical transceiver, including 40G QSFP+ SR4 transceiver, 40G QSFP+ PSM4 transceiver, 120G CXP SR10/SR12 transceiver, 100G QSFP28 SR4 transceiver, 100G QSFP28 PSM4 transceiver, 200G QSFP56 SR4 transceiver, 200G QSFP56 DR4 transceiver, 200G QSFP-DD SR8 transceiver, 200G QSFP-DD PSM8 transceiver, 400G QSFP-DD SR8 transceiver, and 400G QSFP-DD DR4 transceiver, etc.

In general, SR4 series transceivers are connected with 8-core, 16-core, 20-core, or 24-core MPO/MTP OM3/OM4 multimode fiber patch cables, while DR4 and PSM4 transceiver is connected with 8-core or 16-core MPO/MTP single-mode fiber patch cables.

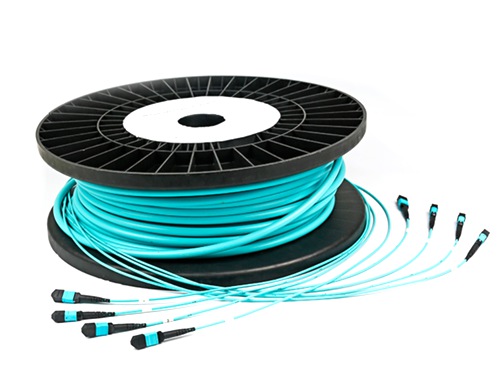

What is MPO/MTP Trunk Cable

In data centers with high-density fiber connections, MPO/MTP trunk cables are often used to centralize cabling. The trunk cable is connected to multiple MPO/MTP patch cords by using an MPO/MTP adapter panel. Like MPO/MTP patch cords, MPO/MTP trunk cables are classified as single-mode or multimode, with multimode being more widely used in practice. The MPO/MTP trunk cable can integrate up to 12x 12-core or 24-core MPO/MTP cables, supports max 144 or 288 fibers.

What is MPO/MTP Breakout Cable

MPO/MTP Breakout cables are mainly used for low bandwidth upgrade to high bandwidth scenarios. All of these scenarios require the use of MPO/MTP breakout cables to connect one high-speed optical transceiver to four or eight low-speed optical transceivers as the data center expands, from 10G to 40G, or from 25G to 100G, or even from 50G to 200G/400G.

For example, one 100G QSFP28 SR4 transceiver can be connected to four 25G SFP28 SR transceivers via an 8-core MPO/MTP to 4-duplex LC multimode breakout cable. Similarly, one 100G QSFP28 PSM4 transceiver is connected to four 25G SFP28 LR transceivers via 8 core MPO/MTP to 4 duplex LC Singlemode breakout cables.

Since most data centers have relatively short internal connections, multimode is more widely used in practice. In addition, today’s data centers largely use LC as a single core fiber connector, therefore, the single-core fiber connector at the breakout end is basically using LC connectors. We offer OM3 and OM4 multimode MPO/MTP breakout cables, as well as 8-, 12- or 24-core Singlemode cables to meet customers’ general and special needs.

Classification By MPO/MTP Polarity

Polarity refers to the matching of the optical transmitter and receiver at each end of the fiber optic link. In conventional cabling systems, connectors such as LC/SC can be easily matched, so there is no polarity problem. However, due to the special design of MPO/MTP connectors, polarity issues must be addressed in high-density MPO/MTP cabling systems. To ensure proper polarity, the TIA 568 standard defines three connection methods, called Method A, Method B, and Method C. Therefore, depending on these methods, there exist MPO/MTP fiber optic cables of different configurations. These MPO/MTP fiber optic cables are usually connected with different MPO/MTP cassettes and fiber optic patch cords to ensure the correct optical path polarity.

Classification By Fiber Type

MPO/MTP cables include multi-mode OM3, OM4, and single-mode types. Multimode OM3/OM4 MPO/MTP fiber optic cables are mainly used for short distances, such as buildings or campuses. The maximum transmission distance at 40Git/s is 100m (OM3) or 150m (OM4). MPO/MTP single-mode optical cable is suitable for long-distance transmission and is widely deployed in operator networks, metropolitan area networks, and PON (passive optical networks). When the modal dispersion is small, the bandwidth of Singlemode is higher than that of OM3/OM4.

Classification By MPO/MTP Cable Jacket

According to different fire protection requirements, MPO/MTP jackets are divided into LSZH (low smoke zero halogens), OFNP (optical fiber non-conductivity, interlayer), CMP (communication multi-purpose optical cable, interlayer), etc. LSZH MPO/MTP optical cable does not contain halogenated materials (toxic and corrosive when burned). Because it provides better protection for personnel and equipment in a fire, it is very suitable for use in confined places. OFNP MPO/MTP optical cable does not contain conductive elements, and is designed with the highest fire rating, and can be installed in ducts and other spaces for building ventilation. CMP MPO/MTP optical cable can limit the flame propagation and smoke emission rate in a fire and is suitable for ventilated spaces. In ventilated spaces, the air circulation of heating and air-conditioning systems is very convenient.

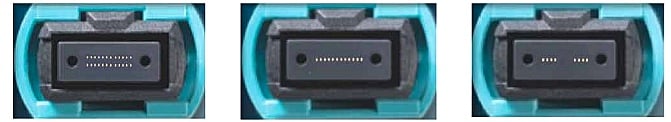

Classification By Fiber Numbers

Commonly used MPO/MTP has 8/12/24 fiber. The 12-fiber MPO/MTP cable is the earliest developed and most commonly used solution for 10G-40G and 40G-100G connections. However, when it is used to connect a 40G QSFP+ module or a 100G QSFP28 module, the middle 4 optical fibers will not be used, resulting in a much lower optical fiber utilization rate than an 8-core optical cable. The 8-fiber MPO/MTP cable system can transmit the same data rate as 12-fiber, but with lower cost and insertion loss, making it a more cost-effective solution. 24-core MPO/MTP fiber optic cable is usually used to establish a 100GBASE-SR10 connection or 400G connection between CFP and CFP optical modules. It allows the use of approved 100GBASE-SR10 fiber technology.

Key Features to Consider

When determining which type of MPO cables will be best for your fiber cabling, keep the following considerations in mind:

- Budget. The amount of your budget determines the complexity of the MPO system and the applications it supports. Flexible designs to accommodate parallel and duplex applications require adequate rack space, cable routing and management, and the right mix of media and performance levels. Reducing the number of connections in your network can lower the total investment cost of your network.

- Polarity. An important consideration in selecting an MPO/MTP is polarity. Polarity is what ensures that your signal transmission will reach the correct receiver. If the polarity is not correct, you will not be able to communicate between the ports that are being connected. With LC connectors, you can flip the fiber on one side of the connector if the port is not working. With MPO connectors, however, you are dealing with (12) or more fibers as well as the connector body; this presents a specific challenge for polarity changes. As a result, managing optical polarity with MPO connectors is increasingly challenging, so it’s critical to get it right from the start!

- Performance. The performance of MPO/MTP fiber cabling systems is very important, especially when running at higher speeds becomes even more important. Insertion loss is a very critical metric, and I recommend carefully checking the “maximum insertion loss” of the MPO/MTP fiber before purchasing it. Insertion loss is a key indicator of the performance of the optical fiber. The lower the insertion loss, the better the optical performance.

Shop MPO/MTP fiber cable from OPTCORE

The different types of MPO/MTP cables in fiber cabling suitable for different devices and scenarios. We hope this guide can help you choose the right cables when you buy new MPO cables and have the flexibility when your networking needs expand.