Blog, Optical Networking

What is OSP Fiber Cable? Everything You Should Know

Every piece of equipment and cable plays a vital role in the world of communication. They enable us to connect with others, share knowledge, and explore new possibilities. OSP fiber cables provide outstanding performance and exceptional stability, even in extreme temperature and humidity conditions, ensuring reliable communication.

This article will explain OSP fiber cables, their types, and the difference between Inside Plant Fiber Cables and answer your questions.

Table of contents

What is OSP?

In residential telecommunications, the term “outside plant” refers to all the physical cables and supporting infrastructure (such as conduit, towers, or poles), as well as associated hardware (such as repeaters), that runs from one demarcation point of a switching facility to the demarcation point of another switching center or customer premises. Simply put, it’s the portion of residential telecommunications between two specific demarcation points involving cables, infrastructure, and associated hardware.

What is OSP fiber cable?

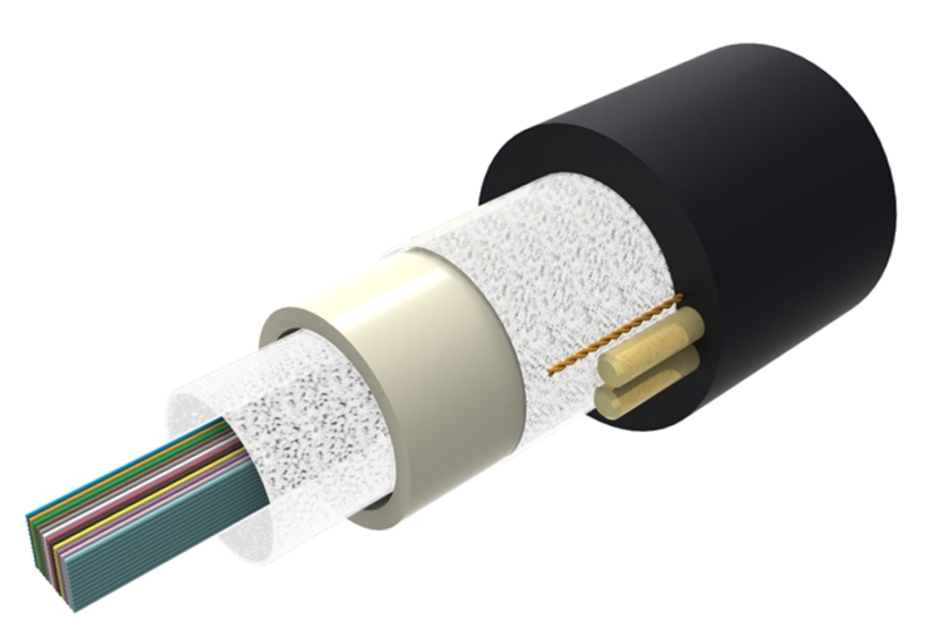

OSP fiber cable, or Outdoor Plant Fiber Cable, is part of an outdoor plant designed for outdoor use. These cables are designed for long-distance, reliable optical signal transmission, connecting different buildings, communication base stations, switching centers, or extending the communication network from the carrier side to the subscriber premises.

OSP fiber optic cables can adapt to complex outdoor environmental conditions. They can withstand different weather conditions (high temperature, low temperature, humidity, sunlight, etc.) and have a certain degree of mechanical strength to cope with the tensile, bending, and external forces during the laying process. As a result, the construction of such cables needs a safety layer, which differs from that of ordinary fiber optic cable.

Types of OSP fiber optic cables

Common OSP fiber optic cables include single-mode, multi-mode, and other type. You can select it according to specific transmission distance requirements, bandwidth needs, and application scenarios.

Classified by fiber optic transmission mode

Single-mode fiber optic cable

- Structural characteristics: This cable usually has only one layer, with the fiber core in the middle wrapped with reinforcing materials. It generally has 24 or fewer fiber cores.

- Transmission characteristics: The core diameter is small, and the optical signal can only be propagated in one mode. The transmission distance and attenuation are also small. This setup makes them suitable for long-distance high-speed data transmission scenarios.

Multimode fiber optic cable

- Structural characteristics: Multiple tubes containing various fiber cores are coupled and surrounded by support or reinforcement materials.

- Transmission characteristics: The larger fiber core diameter can support a variety of transmission modes. Although the transmission distance is relatively short, it provides higher bandwidth at short distances, making it ideal for high-speed data transmission over short distances.

Classification by structure

Center-bundled fiber optic cable

- Structural characteristics: The cable’s center is a loose sleeve with reinforcing components.

- Performance characteristics: Bundle tube material is generally PBT, with hard and flexible characteristics and strong resistance to lateral pressure. Water-blocking tape can prevent water infiltration. Rolled steel belts can resist lateral pressure, tensile, and anti-mouse bite; steel wire enhances the cable’s tensile strength.

- Applicable scenarios: It is suitable for overhead, through the pipe, and other outdoor environments because of its smaller size and lighter weight, making it easy to install and construct.

Stranded fiber optic cable

- Structural features: Multiple bundles of optical fiber equipped in a twisted way are stranded in the center of the reinforcing member. By combining the loose tube, a larger number of cores of fiber optic cables can be obtained, up to more than 1,000 cores.

- Applicable scenarios: It works well for direct burial and pipeline installations where many cores are needed.

Skeleton fiber optic cable

- Structural features: optical fiber embedded in the skeleton groove, high strength.

- Performance characteristics: This optical fiber protection structure is better and can withstand certain external forces, and the arrangement of optical fibers in the skeleton groove is more stable and conducive to transmitting signals.

- Applicable scenarios: suitable for outdoor, directly buried or overhead, and other environments that require high-strength fiber optic cables.

Ribbon fiber optic cable

- Structural features: multiple optical fibers are arranged as a ribbon with a high fiber density.

- Performance characteristics: It can accommodate many optical fibers, meet the needs of large-scale optical fiber laying, and improve communication capacity. The ribbon structure facilitates the splicing and management of optical fibers, reduces the number of splicing points, and improves the reliability of the communication system.

- Application Scenarios: It applies to scenarios that require large-scale optical fiber laying, such as urban backbone communication networks and connections between large-scale data centers.

Classification by installation method and application scenario

Overhead fiber optic cable

- Self-supporting cable: This type of cable includes total media self-supporting fiber optic cable ADSS, which uses its reinforcing components to withstand self-weight and external loads without additional support. These cables use dielectric materials, making them suitable for high-voltage environments and allowing installation along power lines. They are cost-effective and easy to maintain.

- Bundled fiber optic cable includes ground winding optical cable GWWOP, ordinary bundled cable ADL, etc. They are attached to the original ground or phase cable on the optical cable through tape, aramid wire, metal wire, and other bundled fixed, with lightweight, soft, small diameter, and other advantages. They are generally used for the following 35kV line.

Directly buried fiber optic cable

- Structural features: This type of cable is directly buried in the ground, and there is no conduit protection, so it must have rugged and armored protection to withstand the harsh conditions of being buried in the soil and rock. It also needs to have pressure, anti-rodent bites, and other properties.

- Applicable scenarios: They are ideal for long-term burial on city roads, parks, and fields to connect different communication networks.

Pipeline fiber optic cable

- Structural features: Fiber optic cables are laid through pre-laid, urban communication pipes. Pipes can better protect fiber optic cables, reduce damage caused by external factors, and facilitate maintenance and management.

- Application Scenarios: applicable to areas in the city where the communication infrastructure is more complete, can be laid along the roads, buildings, and other pipelines, and fiber optic cables can be laid in them to achieve the coverage of the communication network.

Underwater fiber optic cable

- Structural characteristics: The outer layer usually has a multi-layer protection structure to ensure that the underwater environment is stable for the long term.

- Applicable scenarios: Applicable to the need for underwater communication connection scenarios, such as cross-river, cross-sea communication, etc., to provide communication links between islands, land, and islands.

Key challenges in managing OSP fiber optic networks

Natural Environmental Impacts

- Climatic conditions: Hot summers may cause fiber jacket materials to become soft. Optical fibers’ thermal expansion and contraction create stresses in areas with drastic temperature changes. The stress may lead to micro-bending of the fibers and increased signal attenuation. In addition, heavy rains and floods may cause underground buried optical fibers, and prolonged accumulation of water may damage the protective layer of the optical fiber.

- Natural Disasters: Earthquakes can shift the ground, pulling or twisting underground fiber optic cables. Landslides may directly bury or damage fiber optic cables. Hurricanes may blow down poles, damaging the overhead fiber optic lines. Repairing damage from these disasters can be difficult and take a long time.

Artificial Environmental Disturbances

- Construction activities: Road, building, and other urban construction activities may accidentally damage fiber optic networks. Also, nearby construction work may create vibrations that can affect the stability of the fiber optic connection.

- Theft and vandalism: Unscrupulous people may steal metal materials in optical fibers (e.g., steel wires in the reinforcing cores, etc.). In addition, some malicious vandalism, such as intentionally cutting fiber optic lines, can also cause severe damage to the network.

Network Size and Complexity

- Huge network size: With the continuous growth of communication demand, OSP fiber optic network coverage is getting broader. In big cities, fiber optic networks may extend thousands of kilometers, connecting thousands of user terminals. Managing such a huge network requires recording a large amount of fiber optic line information, which is a great challenge to the management system’s storage and retrieval capability.

- Complex network topology: The topology of the OSP fiber optic network is complex and diverse, including ring, mesh, and other structures. They increase the complexity of network management.

Maintenance and Troubleshooting

- Complex maintenance: Since OSP fiber optic networks are distributed outdoors, personnel must perform maintenance work in different geographical environments and weather conditions. For overhead fiber, maintenance personnel may need to climb poles to check and repair them, which poses a particular safety risk. Underground fiber may require professional detection equipment to find the fault point accurately, and excavation work is also relatively cumbersome.

- Challenging fault location: when the fiber optic network fails, locating the fault point is a complex task. Fiber optic failures may be caused by damage to the fiber itself, loose connectors, equipment failure, and many other reasons. Due to the long fiber optic lines, testing from multiple endpoints may be required. They often use specialized tools, such as Optical Time Domain Reflectometers (OTDRs), to detect signals from the fiber and identify where the fault is.

ISP vs OSP fiber cable: what is the difference

The main differences between inside-plant (indoor) Fiber Cable and outside-plant (outdoor) Fiber Cable are as follows:

1. Environmental Adaptability

Inside Plant Fiber Cable

- Relatively stable temperature environment: In general, indoor fiber cables do not need to cope with the extreme temperature changes that outdoor wires do.

- Less interference from natural factors: Indoor fiber optic cables are not directly affected by natural factors such as wind, sun, rain, and snow. So, in terms of protection, you do not need to have as high as the outdoor fiber optic cable waterproof, sunscreen, and other properties.

- Mechanical protection requirements are lower: The indoor environment is relatively safe, and the risk of physical impact on the cable is lower. Therefore, indoor fiber optic cables do not require as high a level of mechanical resistance in terms of tensile and compressive resistance as outdoor fiber optic cables.

Outside Plant Fiber Cable

- Coping with complex climatic conditions: Outside plant fiber optic cables must be able to withstand a variety of harsh climatic conditions. In cold areas, they should be able to maintain stable performance at extremely low temperatures to prevent the material from becoming brittle and fractured. They should also resist the erosion of heavy rain, snowstorms, sand and dust, and other weather.

- Resistance to natural disasters and human damage: Outdoor fiber optic cables are susceptible to the threat of natural disasters, such as earthquakes, landslides, floods, etc., which may directly damage the fiber optic cable lines. At the same time, it is also necessary to prevent human damage, including road construction, excavation, and other accidental damage. Therefore, outdoor fiber optic cables must be protected by armor to enhance their resistance to external damage.

2. Physical Structure

Inside Plant Fiber Cable

Smaller size and weight: Indoor fiber optic cable is generally slimmer and lighter than outdoor fiber optic cable, as it does not require much protective material.

Relatively simple structure: indoor fiber optic cable usually consists of a fiber optic core, buffer layer, and outer jacket. The buffer layer mainly protects the fiber optic core from minor mechanical damage, while the outer jacket provides some physical protection and flame retardant properties.

Outside Plant Fiber Cable

More complex and sturdy structure: In addition to the fiber core and jacket, reinforcing members, such as steel wires, aramid fibers, etc., increase the tensile strength of the cable to withstand its own weight and external pulling force. At the same time, a waterproof layer or water-resistant tape may be added to prevent rodent bites, and a metal armor layer may also be added.

Larger size and weight: Due to more protective and reinforcing materials, outdoor fiber optic cables are relatively larger in size and weight. For example, some armored outdoor cables may reach several centimeters in diameter and weigh much more than indoor cables.

3. Transmission Performance and Application Scenarios

Inside Plant Fiber Cable

The transmission distance is relatively short, mainly used for short-distance communication connections inside buildings. It can provide sufficient bandwidth to support typical indoor communication applications, such as high-speed Internet access, video conferencing, and internal LAN data transmission. Usually, its bandwidth can meet 1Gbps, 10Gbps, or even higher transmission rates to adapt to indoor communication applications’ current and future needs.

Outside Plant Fiber Cable

OSP fiber cable is designed for long-distance communications, spanning the distance between cities, regions, and even countries. For example, in long-distance communication backbone networks, metropolitan area networks, and other networks, outdoor fiber optic cables can connect different communication nodes, and the transmission distance can reach dozens of kilometers or even hundreds of kilometers.

It must also be characterized by high bandwidth and large capacity to meet large-scale communication needs. It simultaneously transmits many voice, data, and video signals and supports high-speed communication.

FAQ

Q. How do we handle the effects of natural disasters on OSP’s fiber optic network?

A. Plan cabling paths away from natural disaster areas. Reinforce overhead facilities and protect underground OSP cables.

In addition, you can install natural disaster detection equipment and set up an early warning system.

Q. How can we minimize damage to OSP fiber optic networks from construction activities?

A. before construction, you should communicate with the construction unit to understand the OSP fiber optic cable cabling and try to avoid damaging the existing OSP fiber optic network. Construction should also incorporate future fiber network planning. Second, during construction, the location of fiber optic lines must be marked, and professional equipment must be used to detect the location of underground fiber optic lines.

Q. How do you choose a suitable OSP fiber optic cable?

A. Choosing the right OSP fiber optic cable involves more factors to consider. This article mainly refers to the following aspects:

- Transmission distance: long-distance transmission should choose single-mode fiber optic cable because of its small attenuation to meet long-distance transmission requirements. Conversely, multi-mode fiber optic cable is more appropriate for short-distance outdoor fiber optic cable wiring.

- Installation environment: For direct burial installation, choose a cable with armored protection that can resist pressure, moisture, and rodent bites. For overhead installation, you can select the full medium self-supporting fiber optic cable (ADSS). This cable has good insulation, high-temperature resistance, and tensile strength, which makes it suitable for the same pole as the power line. Choosing waterproof, corrosion-resistant, and pressure-resistant cables for underwater installation would be best.

- Mechanical properties: Fiber optic cables with reinforced protection (e.g., armored layers) should be used where they are susceptible to external damage (e.g., vulnerable to excavation or animal infestation).

- Cost and scalability: Choose cost-effective fiber optic cables according to your budget while considering the possibility of future network expansion.

Conclusion

This guide offers insights into outdoor fiber optic cables, detailing the various types available and comparing them to indoor fiber optic cables. We hope this article has increased your understanding of OSP (Outside Plant) fiber optic cables and will assist you in selecting the right outdoor fiber optic cable for your specific needs and environment.