Blog, Optical Networking

How to Clean Fiber Optic Cable Connectors

Initial Published: July 26, 2024

The performance of fiber-optic communications depends significantly on the cleanliness of the fiber-optic connector. Any minute dirt on the connector end face may affect the network transmission rate. It would be best to inspect the connector end face before the fiber starts connecting. If it is dirty, the fiber needs to be cleaned. This article should teach you how to clean fiber-optic cables.

Table of contents

Why is it essential to clean fiber optic connectors?

Fiber optic connectors are vital for fiber optic transmission links and their end faces. If contaminated, it can lead to signal loss and increased return loss, which can affect the overall quality of communication.

Most of the time, there is no guarantee that a new connector in a package is clean enough because there are many sources of contamination. For example, the hands and clothes of the person handling the connector, airborne dust, pollen, grease residue, airborne pollutants, and more. The protective cover used to protect the sealing gasket may contaminate the connector end face. In addition, it is therefore critical to clean the connector end faces to ensure system performance.

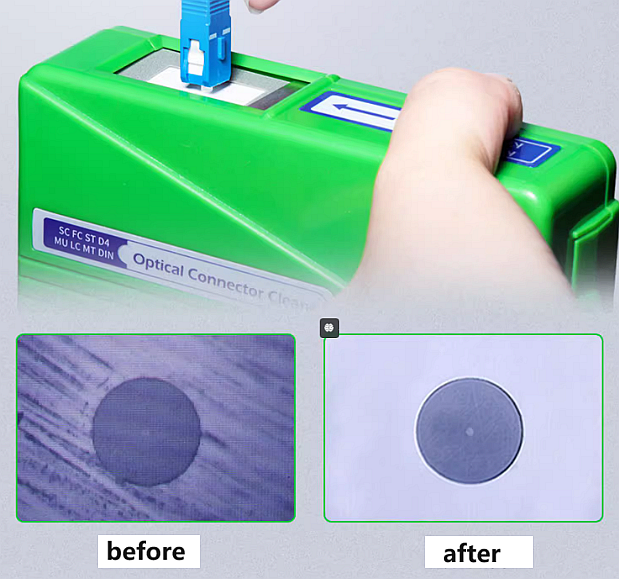

Most contaminants are not visible to the naked eye because of the small diameter of the fiber core, and it is only with the aid of a microscope can we see the full extent of the contaminated fiber core. The figure below shows the contaminated connector end face and the cleaning effect. From the picture, we can see the necessity of cleaning.

Cleaning fiber process

A proper fiber optic cable cleaning process will effectively clean the contamination.

First, the technician puts on lint-free anti-static gloves, inserts the connector to be inspected into the adapter corresponding to the fiber-optic end-face magnifier, and then looks at the center of the fiber-optic connector end-face through the fiber-optic end-face magnifier LCD to see if there is any contamination.

If contamination is in and around the fiber optic end’s fiber core, use the appropriate cleaning method to clean it. Then again, use the fiber optic end face magnifier to check whether the cleaning is effective; if not, re-clean. Until the fiber optic connector is cleaned, it can not be used for fiber optic connection.

Cleaning fiber environment

Before cleaning, first ensure that the working environment is relatively clean. Try to operate in a less dusty or ion-free air environment. Avoid cleaning in high humidity to minimize the risk of contamination. When not in use, keep dust caps on connectors, fiber trays, and other fiber optic components to prevent dust and other contaminants from accumulating. This will also prevent the connectors from being touched and damaged during storage.

Cleaning fiber tools and materials

Basic Tools

- Fiber Optic Cleaner: professional fiber optic cleaning tools, including fiber optic cleaning cassettes and fiber optic cleaning.

- Non-linting cotton pads: These are for wet cleaning to avoid leaving fibers behind.

- Isopropyl Alcohol (lPA): Isopropyl alcohol of at least 99% purity for wet cleaning agents.

Materials to Avoid

- Cotton swabs, paper towels, and other materials that may leave fibers.

- Any material that generates static electricity.

Unrecommended cleaning fiber methods

1. Dry Cleaning Method

This method involves cleaning the fiber optic connector with a dry cloth or cotton swab. This method is effective but has adverse effects. Dry swabs alone may scratch the end face of the fiber optic connector and generate a static charge that is more likely to attract contaminants after wiping.

To reduce the electrostatic charge generated by wet and dry cleaning, the connector end face should be placed in deionized air for 5 to 10 seconds.

2. Wet Cleaning Method

This method uses isopropyl alcohol (IPA) to clean the connector end face. The first problem with IPA cleaning is that it is a poor solvent for some dirt. The second problem is that IPA evaporates slowly and attracts water and other impurities, further slowing the evaporation rate. Also, overuse of IPA solvent can cause the sides of the sealing gasket to become flooded, resulting in cross-contamination of the cleaned end face.

Recommended cleaning fiber methods

1. Combination Cleaning Method

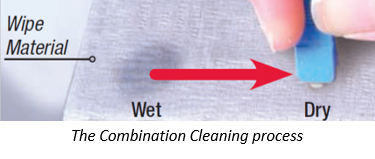

The combination cleaning method is a wet-to-dry cleaning method. First, the technician puts on lint-free, antistatic gloves. The technician then places a rag on a flat surface, drops a small amount of fiber optic cleaning solution onto the rag, and gently strokes the connector end face from the drop to the dry rag. Note that the process maintains a straight-line movement.

2. Special Cleaning Device

Usually, the fiber optic cleaning box is used for male connectors, and the one-touch fiber optic cleaner pen is used for female connectors. As it is not very convenient to use the cleaning box to clean the rack after connection, this time, you can use the cleaning pen suitable for both male and female connectors by adjusting the guide sleeve.

Fiber optic cleaning box cleans fibers:

Press and open the cleaning port masking cover, then gently stroke the fiber core over the cleaning tape several times. Check again that the connector is clean. If it is, it is ready for connection. Otherwise, you can continue cleaning it.

The fiber optic cleaning pen cleans the fiber:

You can use the fiber optic cleaning pen by inserting it into the center of the connector, pressing gently, and then pulling it out when you hear a click.

Check again that the connector is clean. If it is clean, it can be used for connection. Otherwise, you can continue to clean it.

Note: The fiber optic cleaning pen can also be used to clean optical modules, as shown below:

Fiber optic cleaning precautions

- Avoid air pressure cleaning: Do not use a gas gun or compressed air directly; this may cause secondary contamination or leave liquid propellant behind.

- Avoid contamination: Do not touch the fiber optic connector end face with greasy fingers. Do not touch the cleaning area with rags, cleaning cloths, or swabs.

- Avoid blowing in your mouth: moisture and bacteria may further contaminate the connector.

- Storage: When not in use, place the connector protective cover to keep out dust and contaminants.

- Periodic inspection: You should clean the connectors before each connection and disconnection, especially outdoors or in dusty environments.

- Regular maintenance: The device and connectors should be maintained and inspected regularly.

- Cleaning the fiber optic magnifier adapter regularly: gently remove the adapter and clean the contact surfaces with a lint-free fiber optic material.

Conclusion

Keeping fiber optic connectors clean is essential to ensuring network performance. These steps and recommendations can effectively reduce signal attenuation and reflection caused by connector contamination. Regular cleaning and maintenance will extend connector life and ensure a stable and efficient network.

Read more:

- Fiber Connector Types: A Complete Guide

- MTP vs MPO connector: What is the difference?

- What is Optical Transceiver: A Beginner Guide (2024)

- MPO/MTP Fiber Patch Cable Types and Applications