Optical Networking

Fiber Connector Types: A Complete Guide (2024)

Updated: November 28, 2024

When it comes to fiber optic connectors, it’s easy to get confused about the various types and their applications. That is why I am writing this guide. I have gathered information from all over to assist you in understanding everything about them.

After reading this guide, you will understand the following:

Table of Contents

- What is fiber connectors?

- SC connector

- LC connector

- FC connector

- ST connector

- MPO connector

- MTP connector

- MT-RJ connector

- MU connector

- E2000 connector

- VSFF connector

- MDC connector

- CS connector

- SN connector

- DIN connector

- D4 connector

- ESCON connector

- FDDI connector

- SMA connector

- Q-RMC Connector

- Other Fiber Connector Types

- Non-Contact Fiber Connector

- How to choose?

- FAQs

Let’s get to work.

What is a Fiber Connector?

The fiber connector is called a fiber optic or optical fiber connector. It is a precise coupling device that joins fiber optic cables quickly, enabling faster connection and disconnection than splicing. The connector mechanically orients the fiber cores, allowing light to pass and travel through the cable without interruption.

Unlike electrical connectors, fiber optic connectors allow light signals instead of electrical signals, which requires the connector to be much more precise. They have low insert loss, the best insertion repeatability, high return loss, and a long lifetime.

Although manufacturers have launched over 100 fiber connectors, only a few types are the industry’s most popular and widely used. Next, we will discuss the main types of fiber optic connectors.

Structure of Fiber Connectors

Before going to the main section, let us explore the fiber connector structure. Although different fiber connectors have different structures, they generally share four essential parts: a ferrule, a connector, an attachment mechanism, and boots. The images below show the details of a typical SC connector.

SC Connector

The SC (Standard Connector, Subscriber Connector) is a fiber optic connector released by NTT in the mid-1980s. It is a snap-on square connector with a simple push-pull motion, similar to the push-pull latching mechanism of ordinary audio and video cables. It uses a 2.5mm diameter ferrule, twice the size of the later-developed LC connector.

Initially used in Gigabit Ethernet networks, the SC connector was adopted by the TIA-568-A specification in 1991. It has slowly gained popularity as manufacturing costs have decreased. Due to its outstanding performance, it has dominated the fiber optic field for decades. Still, In today’s fiber optic networks, SC connectors are among the two most common fiber optic connectors.

Due to the larger size of this connector, which requires more space for the same number of ports, it has slowly been replaced by more modern, streamlined connectors, such as LC and MPO connectors.

LC Connector

LC stands for “Lucent Connector.” Like its name, it was developed by Lucent Technologies. The LC connector has a 1.25mm ferrule, which is half the size of the SC. This small form-factor connector is extremely popular in datacoms and is perfect for high-density applications.

Nowadays, many people prefer high-efficiency cabling with LC fiber optic connectors. They are currently the most often used and successful ones.

Modern optical transceivers and active networking components feature LC connectors, expanding massive deployments and applications.

FC Connector

FC stands for “ferrule connector”. It is the first fiber optic connector to use a ceramic ferrule. However, unlike the plastic-bodied SC and LC, it uses a circular screw-type fitting made of nickel-plated or stainless steel. The end face of the FC fiber optic connector is inserted using an alignment key and then screwed into the adapter/jack using a fiber collet.

Despite the added complexity of manufacturing and installation, FC connectors still offer options for precision instruments such as OTDRs. In addition, FC’s screw-in collet is ideal for application scenarios in high-vibration environments because it ensures a solid fit with a spring-loaded collar.

It was initially designed for data center and telecom applications, but its use has declined since the advent of SC and LC fiber optic connectors. That is because it costs more, and the connection speed is slower than the SC and LC.

ST Connector

AT&T developed and licensed the ST (Straight Tip) fiber connector shortly after introducing the FC type. It features a bayonet mount and a long cylindrical 2.5mm ceramic ferrule to retain the fiber. Because ST is spring-loaded, you must ensure that it is correctly seated. If you have a lot of loss, reconnect it to see if it helps.

ST connectors are commonly suitable for long-distance and short-distance applications, such as campuses and developing multimode fiber applications, enterprise networks, and military applications.

MPO Connector

MPO stands for Multi-fiber push-on connector. Unlike the conventional fiber connector, an MPO connector includes a fiber array that supports multiple fibers up to 12, 24, or 36 strands.

Due to their complexity, Multi-fiber connectors are not yet suitable for field-fit applications and must be factory-terminated. They are widely used in high-density data centers or fiber cabling systems that require space-saving.

Although the total cabling pricing is much higher than standard LC, SC, or FC connectors, the MPO fiber optic connector provides significantly fast deployment and inexpensive cost based on a ”per-fiber” basis.

MTP Connector

MTP® is a registered trademark of US Conec; it is an enhanced MPO connector, an abbreviation for Multi-fiber Termination Push-on. Compared with MPO, the MTP connector is an enhanced version of the Multi-fiber connector with improved accuracy, proven dependability, and better performance. Of course, its pricing is higher than the standard MPO.

Further Reading

MT-RJ Connector

MT-RJ stands for Mechanical Transfer Registered Jack. It is a duplex connector with female and male variants employing alignment pins. MT-RJ is almost no longer in use. Specific systems, however, may still require these connectors for maintenance. MT-RJ is only compatible with multimode duplex cables. Both fibers enter the ferrule, connected to its mated half via pins and holes, much like the MPO/MTP connector.

MU Connector

The MU (Miniature Unit Coupling) connector was developed by NTT, just like the Mini-SC. But unlike the SC, the MU connector has a 1.25mm zirconia ferrule. It uses a simple push-pull design, a compact miniature body, and a self-holding mechanism for backplane applications.

E2000 Connector

Diamond SA developed the E2000 connector. Also known as an LSH connector, it features a spring-loaded shutter mechanism to protect the ferrule end face from dust and laser beams. The E2000 fiber optic connector has a one-piece design for easy and quick termination and is suited for high-safety and power applications.

VSFF Connector

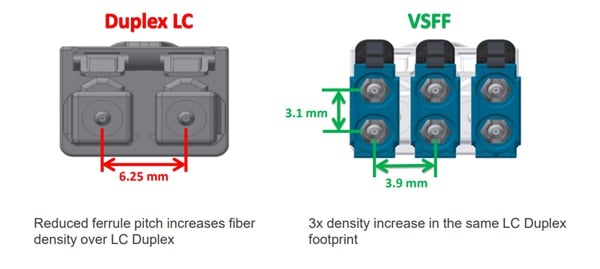

VSFF stands for Very Small Form Factor, a new term used to meet the increasing demands of hyper-scale and enterprise data centers.

According to CORNING, VSFF connectors are compact fiber optic connectors designed for small spaces. They are helpful in fiber network applications where space is limited.

SN, CS, and MDC are the most common types of VSFF connectors. In the following sections, we introduce those three types in detail.

These VSFF connectors are designed to meet the high demands of 200G/400G/800G data centers. The typical application scenarios include the VSFFC transceivers (such as QSFP-DD and OSFP), VSFFC fiber patch cables, and assemblies.

MDC Connector

Short for the miniature duplex connector, the MDC connector was created by US Conec. It is a Push-Pull-Boot duplex fiber connector using industry-standard 1.25mm ferrule while providing three times the density of LC connectors.

As part of the Very Small Form Factor (VSFF) connectors portfolio, it targets SFP-DD, QSFP-DD, OSFP transceivers, and other high-density patching applications.

CS Connector

The CS connector is a new high-density, very small form factor (VSFF) fiber optic connector for QSFP-DD, OSFP, and COBO transceivers. Compared to an LC duplex, it delivers a 40% size reduction and doubles the density of patch panels.

Further Reading

SN Connector

The SN connector is a new duplex fiber optic connector developed by SENKO. It delivers higher density than the CS connector, using the industry-standard 1.25mm ferrule but reduced ferrule pitch; therefore, it offers a 4x duplex fiber connector with the same LC size. It is ideal for next-generation hyper-scale data centers, Edge, Enterprise, or co-location DCI.

DIN Connector

DIN stands for Deutsches Institut für Normung, or German Institute for Standardization, a German manufacturing industry standards body. DIN connector is the fiber optic connector compatible with DIN 47256. These fiber connectors are rare, and very few users are in the market.

D4 Connector

The D4 connector is an older-generation single-mode fiber optic connector developed by NEC. It was most likely the first connector to use ceramic ferrules thinner than SCs or FCs. It was widely used in telecom networks from the 1980s through the early 1990s, and part of it may still be in use today.

ESCON Connector

IBM developed Enterprise Systems Connection (ESCON) in the early 1990s as a serial half-duplex optical fiber interface to improve connectivity by incorporating fiber optics into a network. The ESCON fiber optic connector uses 2.5mm ferrules to mate with SC or ST connectors via fiber adapters. However, to this day, ESCON is being displaced by the industry’s newer and more efficient SC and LC connectors.

FDDI Connector

FDDI is an abbreviation for Fiber Distributed Data Interface, which refers to a local area network technology such as Ethernet or Token Ring. Like the ESCON connector, the FDDI connector, also known as a MIC (Media Interface Connector) connector, is the termination on the fiber optic cable itself. It has two ferrules in a huge, heavy plastic housing with a squeeze-tab retention mechanism.

SMA Connector

SMA is the acronym for “Subminiature A,” Amphenol created in the late 1970s. The ferrule of the model SMA was precisely 1/8 inch in diameter and mated in a machined adaptor. When the adapters were not accurate enough for superior fiber performance, a necked-down ferrule coupled with a Delrin adapter was used.

Because of its key drawbacks, the SMA fiber connector is a commonly used multimode fiber with a very tiny market share. It is used only in minimal medical, materials processing, spectroscopy, sensing, and quality inspection applications.

Q-RMC Connector

The Q-RMC, or Rosenberger Multifiber Connector, is a durable industrial connector that uses the multi-fiber MT ferrule from the MTP®/MPO connector. It can accommodate up to 24 fiber cores. The connector features a push-pull closing mechanism, making connecting even in tight spaces easier and quicker.

With IP67 protection, it is waterproof, dustproof, and corrosion-resistant. It is suitable for use in extreme temperature environments (-40~80℃). Because of these qualities, it is ideal for industrial, mining, mobile communication (FTTA), 5G Base Stations, broadcast, and intelligent grid cabling applications.

Other Fiber Connector Types

The above fiber connector types are classified based on shape and appearance. This categorization is also the most common among industry readers and professional users. However, besides those terms, we can also categorize the fiber optic connector into various terms. Now, let us briefly introduce some of them.

1. Classified By Fiber Mode: Single Mode vs Multimode Fiber Connector

Multimode fiber uses a 50μm or 62.5μm fiber core to allow multiple modes of transmission at a time. The multimode connector is suitable for the multimode fiber of OM1, OM2, OM3, OM4, and OM5. In most cases, the multimode connector is less expensive than a single one, increasing its popularity and lowering the system cost for connectivity.

Similar to single-mode fiber construction, single-mode fiber connectors use single-mode fiber with a smaller core diameter, typically 9 microns. This allows the connector to transmit only one mode of the light signal, thus reducing intermodal dispersion. It is usually suitable for medium—to long-distance data transmission.

2. Classified By Fiber Count: Simplex vs Duplex Fiber Connector

A simplex fiber connector consists of only one single fiber connector. It is usually used for transmitting or receiving data in one direction but does not allow the duplex to work. However, the BiDi transceiver uses WDM technology to enable bidirectional transmission with only a simplex connector.

Unlike the simplex connector, a duplex connector consists of a pair of fiber connectors for the transmitter and receiver simultaneously. This connector is used for most cases since the network usually needs to transmit and receive the data simultaneously.

However, please note that most duplex fiber connectors have retaining clips. Users can easily detach the carabiner, transforming it into two simplex connectors.

3. Classified By Application Scenario: Waterproof and Regular Fiber Connector

Unlike regular fiber connectors, Waterproof fiber optic connectors use specially designed mechanical structures with sealing mechanisms such as O-rings or gaskets to prevent the intrusion of moisture and dust, thus ensuring waterproof and dustproof performance. They are typically used in harsh outdoor environments such as outdoor telecommunications, industrial environments, marine and submarine deployments, and security surveillance.

4. Classified By Termination: Field-terminated vs Pre-terminated Fiber Connector

Field termination refers to making fiber optic connections directly at the installation construction site. Field termination connectors are typically designed for quick and easy assembly. sometimes called fast fiber connectors, are the most common type and include the LC, SC, FC, and ST types.

They are suitable for use in a variety of environments. This type of connector is simple to construct, requires fewer tools, and is easy to carry and operate. It can be installed quickly in the field, saving time and labor costs and providing great flexibility.

Pre-terminated connectors are factory-terminated connectors that have already been assembled, connected, and tested at the factory. Users only need to carry out simple installation in the field. Pre-terminated connectors are typically used where high reliability and stability are required or where fiber optic cabling needs to be deployed in bulk, such as data centers or large network deployments. They can reduce the efficiency of providing on-site construction, reducing complexity and potential errors.

5. Classified By Fiber Endface Polish: APC, UPC, PC Fiber Connector

The APC fiber connector was polished with Angled Physical Connect, the UPC connector was polished with Ultra Physical Contact, and the PC connector comes with Physical Contact. Check our blog to learn the details.

Please note that the PC and UPC connectors are the most popular types for most applications and are usually provided as the default type. The APC connector is usually used for broadcast and FTTH applications.

Non-Contact Fiber Connector

We also see some enterprises develop non-contact fiber connectors.

Unlike the regular fiber optic connector, the non-contact fiber connector doesn’t require physical contact between the fiber end-face or a beam-forming lens. Thereby achieving lower insertion loss, improved return loss, assured random mating, and dust and dirt immunity. However, this new style connector has barely been deployed because of the much higher cost and manufacturing complexity.

How To Choosing a Fiber Connector?

Still, trying to figure out how to choose the correct fiber optic connector? Check the following helpful steps.

Step 1: Know the fiber count and connector type

Choose the connector type based on your existing equipment and long-term plans. Select the LC connector if you are using the most common SFP module. If you use a QSFP28 module, you may choose an MPO or LC connector. SC and LC are the most common choices. MPO is for high-throughput data centers, and VSSF connectors such as CS and SN are for 400G and beyond fiber cabling applications.

Step 2: Know the fiber type

Like fiber cables, they can be commonly categorized into single-mode and multimode fiber connectors.

Single mode fiber connector permits one light mode to propagate simultaneously, offering the longest transmission distance.

The multimode connector allows many light modes to propagate through the fiber, supporting a very short distance but lowering cabling costs.

Those fiber connectors usually have different color codes for easy identification. Single-mode connectors typically have blue or green covers, while OM1/OM2 multimode connectors have beige covers, OM3 has aqua, and OM4 has magenta.

Step 3: Know the polish type

Remember the Polish type. Fiber optic connectors are available in PC, UPC, and APC polish. Therefore, we can divide them into three categories: PC, UPC, and APC connector; different polishes offer different performance and cost differences. Check with your supplier before ordering.

Identifying these three connector types is made convenient by the color code:

- Black is for the PC connector

- Green is for APC connector

- Blue is for UPC connector

- Beige is for multimode PC or UPC connector

- Aqua is for OM3 PC or UPC connector

Remember that different manufacturers may have varying color coding conventions for fiber connectors, so it’s important to always double-check before ordering.

Further Reading

FAQs

Q: What should I do if I install an SC connector but require an LC type?

A: In this case, you may use a fiber optic adapter like an SC-LC hybrid, which converts the SC to an LC connector.

Q: How do you connect fiber optic cable to the connector?

A: Take the LC fiber cable as an example. First, move the dust cover, then insert it into the LC connector carefully. Don’t touch the fiber end face to avoid any dirt.

Q: How do you connect two fiber optic cable connectors?

A: You need a suitable fiber optic adapter, such as connecting two LC fiber cables via an LC fiber adapter or an LC-SC fiber adapter to connect the LC and SC fiber cables.

Q: Why so many fiber optic connectors?

A: Indeed, many fiber connector types for different applications vary with the time change. However, modern fiber optic connectors generally include SC, LC, and MPO connectors. The others have fewer deployments.

Conclusion

Although we have introduced the most common fiber optic connector, many more types exist in the industry, such as OptiJack, NTT SC-P, 3M Volition, Sumitomo Mini BNC, AMP Optimate DNP, etc. In most cases, we will not encounter the other fiber optic connectors. So remember the most common connectors and know the difference is enough.

As a professional fiber optic supplier, Optcore offers a comprehensive portfolio of fiber optic cables with different connector types. They all have passed the industry standard test to deliver optimal performance and reliability. You may trust our total fiber optic connectivity solution from this optical transceiver connectivity, like SFP, QSFP, and QSFP28, to the high-density fiber system, including 10G, 100G, and 400G.

Reference:

- https://www.thefoa.org/tech/connID.htm

- https://www.usconec.com/media/1402/mdc-brochure.pdf

- https://www.ieee802.org/3/db/public/adhoc/presentations/mitcheltree_3db_adhoc_01_070920.pdf

- http://csconnector.net/

Read more:

- APC vs UPC vs PC Fiber Connector, What is the Difference?

- What is SFP Module? An Ultimate Guide

- Single Mode vs Multimode Fiber, What is The Difference?

- OS1 vs OS2 Fiber, What is the Difference?

- Fiber Color Code: A Simple Guide for Beginners

- MTP vs MPO connector: What is the difference?

Español

Español 日本語

日本語 Français

Français Deutsch

Deutsch

Thanks for making this available to us

What is the best solution for a high vibration industrial environment? Do you have any information comparing plug type and performance under different vibration environments? And by the way, great blog, thanks for gathering all this info into a single spot !

Is there a metal free solution, for example an LC plug without a metal spring or some other type that has no metal element in the assembly? // thanks for any help

Thank you for taking the time to share your wealth of information in a well organized and comprehensible manner for those of us who are looking for exactly what you’ve shared. Thank you for your time.

Your article is very helpful for us. I can figure out my wifi problem now my issues are resolved. Thank you for the amazing article.