Blog, Network Cabling

American Wire Gauge: What It Means in the DAC?

Updated: December 2, 2024

When choosing an Ethernet cable or Direct-Attach Cable (DAC), many people usually only consider the cable type and transmission distance and ignore the size and thickness of the cable. Is there a standard for selecting cable size? AWG, or American Wire Gauge, is the standard way of expressing wire size in North America.

In this article, we’ll provide information about AWG and show you how to choose the suitable cable for your needs.

Table of contents

What is AWG?

The American Wire Gauge (AWG), introduced in 1857, is the standard way of representing North American wire sizes. Contrary to common sense, the larger the number in AWG, the smaller the wire diameter and thickness. For example, 24WG wire is thicker than 28WG wire. That is, the physical size is inversely proportional to the number.

The AWG system has 44 standardized wire sizes, with 0000 (4/0)AWG being the largest and 40 AWG being the smallest.

Table of AWG sizes and characteristics

Table 1 lists the AWG Metric Conversion chart(AWG to mm2). In addition to wire size, the table provides load (current) carrying capacity, maximum frequency, etc.

| AWG | Diameter | Area | Weight(Kg/m) | Turns Of Wire (Per/in) | Max Frequency for 100% skin depth | Max Current [Amperes] |

| 0000 (4/0) | 0.46″ (11.7mm) | 212 kcmil (107mm²) | 0.953 | 2.17 | 125 Hz | 302 |

| 000 (3/0) | 0.41″ (10.4mm) | 168 kcmil (85 mm²) | 0.756 | 2.44 | 160 Hz | 239 |

| 00 (2/0) | 0.365″ (9.27mm) | 133 kcmil (67.4 mm²) | 0.599 | 2.74 | 200 Hz | 190 |

| 0(1/0) | 0.325″ (8.25 mm) | 106 kcmil (53.5 mm²) | 0.475 | 3.08 | 250 Hz | 150 |

| 1 | 0.289″ (7.35 mm) | 83.7 kcmil (42.4 mm²) | 0.377 | 3.46 | 325 Hz | 119 |

| 2 | 0.258″ (6.54 mm) | 66.4 kcmil (33.6 mm²) | 0.299 | 3.88 | 410 Hz | 94 |

| 3 | 0.229″ (5.83 mm) | 52.6 kcmil (26.7 mm²) | 0.237 | 4.36 | 500 Hz | 75 |

| 4 | 0.204″ (5.19 mm) | 41.7 kcmil (21.2 mm²) | 0.188 | 4.89 | 650 Hz | 60 |

| 5 | 0.182″ (4.62 mm) | 33.1 kcmil (16.8 mm²) | 0.149 | 5.5 | 810 Hz | 47 |

| 6 | 0.162″ (4.12 mm) | 26.3 kcmil (13.3 mm²) | 0.118 | 6.17 | 1100 Hz | 37 |

| 7 | 0.144″ (3.66 mm) | 20.8 kcmil (10.5 mm²) | 0.0938 | 6.93 | 1300 Hz | 30 |

| 8 | 0.128″ (3.26 mm) | 16.5 kcmil (8.37 mm²) | 0.0744 | 7.78 | 1650 Hz | 24 |

| 9 | 0.114″ (2.91 mm) | 13.1 kcmil (6.63 mm²) | 0.059 | 8.74 | 2050 Hz | 19 |

| 10 | 0.102″ (2.59 mm) | 10.4 kcmil (5.26 mm²) | 0.0468 | 9.81 | 2600 Hz | 15 |

| 11 | 0.0907″ (2.30 mm) | 8.23 kcmil (4.17 mm²) | 0.0371 | 11 | 3200 Hz | 12 |

| 12 | 0.0808″ (2.05 mm) | 6.53 kcmil (3.31 mm²) | 0.0294 | 12.4 | 4150 Hz | 9.3 |

| 13 | 0.0720″ (1.83 mm) | 5.18 kcmil (2.62 mm²) | 0.0234 | 13.9 | 5300 Hz | 7.4 |

| 14 | 0.0641″ (1.63 mm) | 4.11 kcmil (2.08 mm²) | 0.0185 | 15.6 | 6700 Hz | 5.9 |

| 15 | 0.0571″ (1.45 mm) | 3.26 kcmil (1.65 mm²) | 0.0147 | 17.5 | 8250 Hz | 4.7 |

| 16 | 0.0508″ (1.29 mm) | 2.58 kcmil (1.31 mm²) | 0.0116 | 19.7 | 11 k Hz | 3.7 |

| 17 | 0.0453″ (1.15 mm) | 2.05 kcmil (1.04 mm²) | 0.00922 | 22.1 | 13kHz | 2.9 |

| 18 | 0.0403″ (1.02 mm) | 1.62 kcmil (0.823 mm²) | 0.00732 | 24.8 | 17 kHz | 2.3 |

| 19 | 0.0359″ (0.912 mm) | 1.29 kcmil 0.653 mm²) | 0.0058 | 27.9 | 21 kHz | 1.8 |

| 20 | 0.032″ (0.812 mm) | 1.02 kcmil 0.518 mm²) | 0.0046 | 31.3 | 27 KHz | 1.5 |

| 21 | 0.0285″ (0.723 mm) | 0.810 kcmil (0.410 mm²) | 0.00365 | 35.1 | 33 kHz | 1.2 |

| 22 | 0.0253″ (0.644 mm) | 0.642 kcmil (0.326 mm²) | 0.00289 | 39.5 | 42 KHz | 0.92 |

| 23 | 0.0226″ (0.573 mm) | 0.509 kcmil (0.258 mm²) | 0.00229 | 44.3 | 53 KHz | 0.729 |

| 24 | 0.0201″ (0.511 mm) | 0.404 kcmil (0.205 mm²) | 0.00182 | 49.7 | 68 kHz | 0.577 |

| 25 | 0.0179″ (0.455 mm) | 0.320 kcmil (0.162 mm²) | 0.00144 | 55.9 | 85 kHz | 0.457 |

| 26 | 0.0159″ (0.405 mm) | 0.254 kcmil (0.129 mm²) | 0.00114 | 62.7 | 107 kHz | 0.361 |

| 27 | 0.0142″ (0.361 mm) | 0.202 kcmil (0.102 mm²) | 0.000908 | 70.4 | 130 kHz | 0.288 |

| 28 | 0.0126″ (0.321 mm) | 0.16 kcmil (0.081 mm²) | 0.00072 | 79.1 | 170 kHz | 0.226 |

| 29 | 0.0113″ (0.286 mm) | 0.127 kcmil (0.0642 mm²) | 0.000571 | 88.8 | 210 kHz | 0.182 |

| 30 | 0.01″ (0.255 mm) | 0.101 kcmil (0.0509 mm²) | 0.000453 | 99.7 | 270 kHz | 0.142 |

| 31 | 0.00893″ (0.227 mm) | 0.0797 kcmil (0.0404 mm²) | 0.000359 | 112 | 340 kHz | 0.113 |

| 32 | 0.00795″ (0.202 mm) | 0.0632 kcmil (0.032 mm²) | 0.000285 | 126 | 430 KHz | 0.091 |

| 33 | 0.00708″ (0.18 mm) | 0.0501 kcmil (0.0254 mm²) | 0.000226 | 141 | 540 KHz | 0.072 |

| 34 | 0.00630″ (0.16 mm) | 0.0398 kcmil (0.0201 mm²) | 0.000179 | 159 | 690 kHz | 0.056 |

| 35 | 0.00561″ (0.143 mm) | 0.0315 kcmil (0.0160 mm²) | 0.000142 | 178 | 870 KHz | 0.044 |

| 36 | 0.005″ (0.127mm) | 0.025 kcmil (0.0127 mm²) | 0.000113 | 200 | 1100 KHz | 0.035 |

| 37 | 0.00445″ (0.113 mm) | 0.0198 kcmil (0.01 mm²) | 0.0000893 | 225 | 1350 kHz | 0.0289 |

| 38 | 0.00397″ (0.101 mm) | 0.0157 kcmil (0.00797 mm²) | 0.0000708 | 252 | 1750 kHz | 0.0228 |

| 39 | 0.00353″ (0.0897 mm) | 0.0125 kcmil (0.00632 mm²) | 0.0000562 | 283 | 2250 KHz | 0.0175 |

| 40 | 0.00314″ (0.0799 mm) | 0.00989 kcmil (0.00501 mm²) | 0.0000445 | 318 | 2900 kHz | 0.0137 |

Common American Wire Gauges and Their Applications

Below is a breakdown of some standard wire gauges and their typical uses. Choosing the right gauge ensures that your electrical system and all the equipment it connects to will operate efficiently and safely.

- 18 AWG: This thin wire is commonly used for low-voltage applications such as doorbells, LED lighting, and thermostats.

- 16 AWG: It is used in slightly higher-current applications such as small appliances, lighting extension cords, etc.

- 14 AWG: This is one of the most widely used wire gauges for home wiring. It is commonly used for 15-amp lighting circuits and bedroom and office outlets.

- 12 AWG: This is a slightly thicker wire used for 20-amp circuits, kitchen appliances, bathroom outlets, and other outdoor applications.

- 10 AWG: This thicker, high-power wire is used for 30-amp circuits, clothes dryers, small electric ovens, and window air conditioning units.

- 6 to 8 AWG: They are used for high-current applications such as large motors, large HVAC systems, electric vehicle charging stations, and central air conditioning units.

- 4 AWG and above: These thick wires are used for high-current circuits. They are typically used in large industrial equipment, residential service panels, sub-panels, high-current welding equipment, and large battery packs.

Why is AWG important?

The larger the cross-section of the wire, the lower its resistance, which means it can travel longer distances and support higher data transfer speeds.

The larger the wire gauge, the more current it can carry. Knowing the wire gauge allows you to determine the amount of current that can be taken while ensuring that the wire is not damaged.

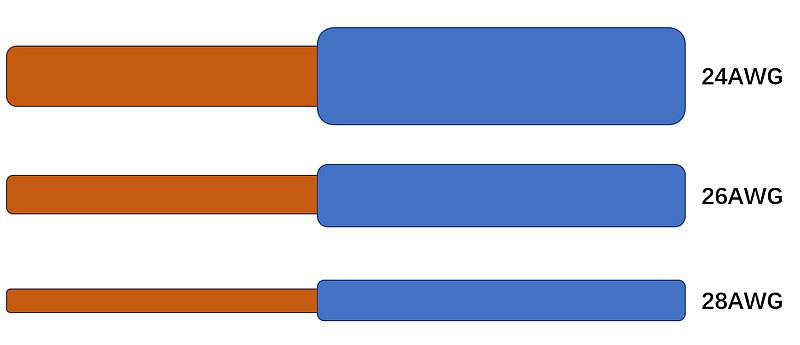

24AWG vs. 26AWG vs. 28AWG Ethernet cables, how do I choose?

Cat5e cables typically run between 24 and 26 AWG, Cat6 and Cat6A usually run between 22 and 26 AWG, and Cat8 electric cables run between 26AWG and 28AWG.

24AWG cables are the largest size, have low resistance and high power, and are suitable for long-distance high-speed or short-distance high-performance transmission.

26AWG is the more popular cable size, usually found in stranded cables. Compared to 24AWG, it is slimmer and more flexible and is suitable for short-distance transmission or cabling locations where flexibility is required. An example is our Cat6 shielded Ethernet cable.

28AWG cable is the thinnest and one of the most flexible cables for short-distance data transmission. It is ideal for saving space or installing a patch panel.

Choosing the suitable DAC cable

DAC cables are available in 24AWG, 28AWG, and 30AWG. The lower American Wire Gauge(AWG) values are thicker and less bendable than the higher. Thicker wires also reduce electrical resistance, supporting higher data transmission speed over longer distances with less signal loss. However, thicker AWG cables can be more expensive, less pliable, and more flexible.

In conclusion, AWG is a crucial factor to consider when choosing DAC cables for your network infrastructure.

Conclusion

Understanding American Wire Gauge(AWG) is critical for Ethernet users when choosing a suitable DAC cable. Usually, Longer Ethernet cable runs require lower AWGs, while shorter patch cords require higher AWGs.

Reference